A guide to replacing a faulty point on a completed layout. Initially published in issue 290 of Model Rail Magazine.

Time required: 2-3 hours.

Tools: Dremel with cutting disk, soldering iron, pliers, side cutters, old chisel, mini hoover.

My layout ‘Tedford & Bearham’ is now approaching 15 years old. Some of the track was salvaged from a previous layout and there have been numerous alterations and additions over the years. During a recent running session a loco came to an abrupt halt on a point and it quickly became clear that there was a problem. This particular point had suffered damage to its tie bar at some point in the past and I had attempted to make a repair with glue to hold the pin from the point motor to the tie bar. This repair had failed and the loco had hit a part of the tie bar that was sticking up and fouling the kadee coupling. There was no alternative but to replace the point. This guide shows how I replaced the point without damaging the surrounding track work. This process will also work for replacing damaged plain track or crossovers.

The problem – These pictures show the damage to the tie bar and the location of the point within a complex junction.

Step 1 – Nearby details such as a catenary mast were removed and a suitable replacement point was obtained. Be sure to get an identical replacement otherwise the alignment will be different.

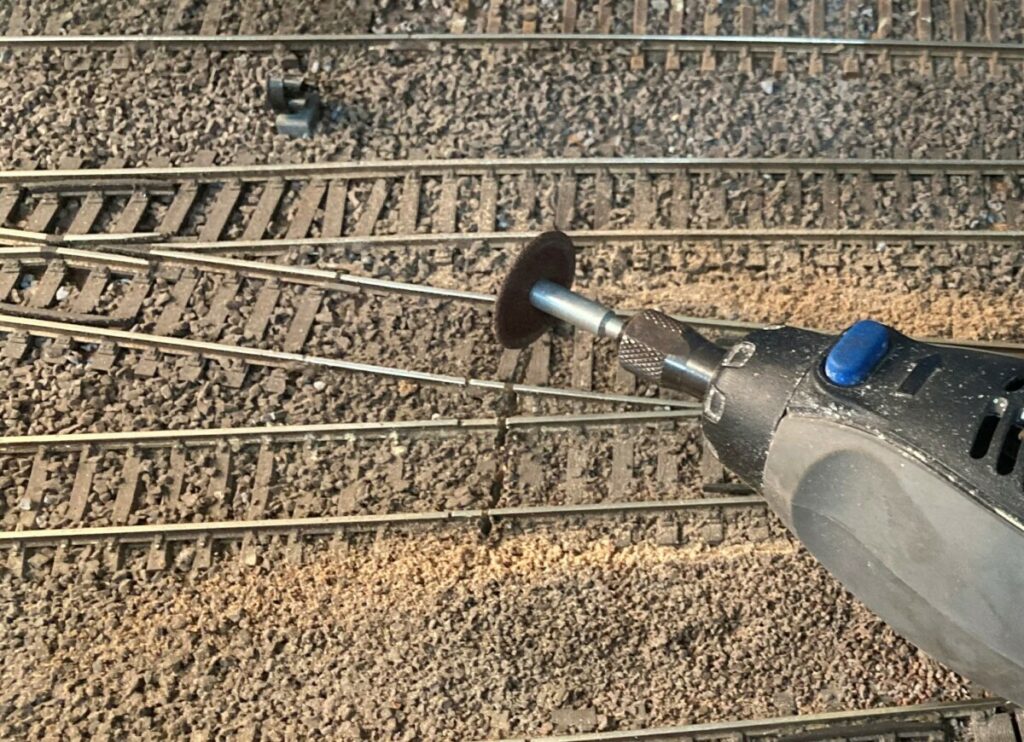

Step 2 – Use a cutting disk in a dremel to carefully cut a slit through the ballast around the edge of the damaged point. This will prevent adjacent ballast being disturbed when removing the point. Caution: Wear eye protection.

Step 3 – Use the cutting disk to cut through the rails and sleepers about 1cm in from the end of the point being removed. Cut the rail that is a part of the point, not the adjacent track, you don’t want to damage the adjacent track.

Step 4 – Pull out any track pins and gently lift up the main section of the damaged point. If you have any power dropper wires soldered on you will need to remove these, in my case they were soldered to the end parts that are still in situ at this stage.

Step 5 – The remaining end sections of rail now need to be removed. In my case my track joints are soldered, which makes this a little more difficult. Use a soldering iron to carefully heat up the joint, heating the main section of rail on the adjacent track. Then use side cutters or angled pliers to pull out the end of rail to be removed. This should come out with the fishplate, leaving a clean end to the adjacent rail. If there are dropper wires these should be disconnected at this stage.

Caution: Be careful with the soldering iron to avoid damage to the sleepers. Also beware that the joint being removed will suddenly come free so it is possible the rail being removed will move quickly resulting in damage to adjacent scenery and a scuff to your hand holding the side cutters as it skids across the ballast.

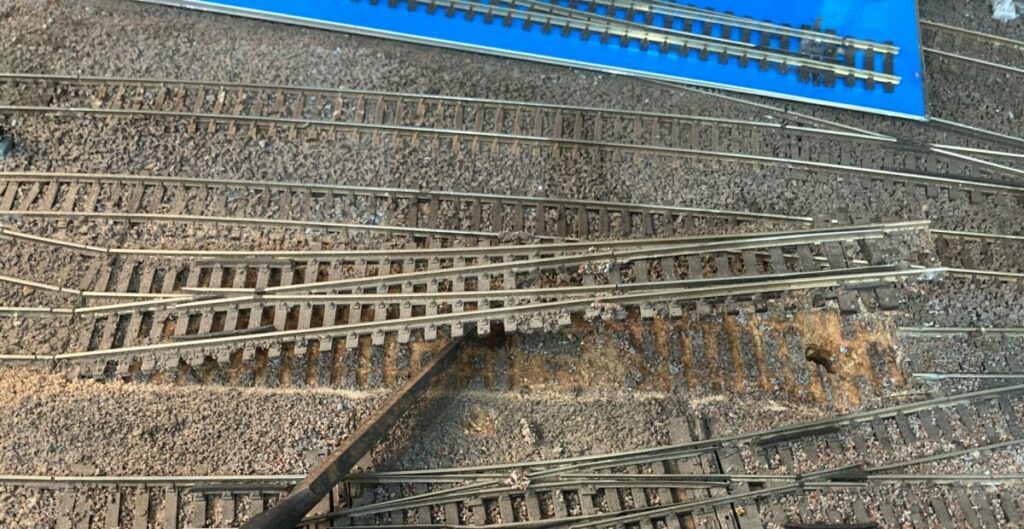

Step 6 – Using an old chisel remove the ballast from the area where the point was. Clear this away with a mini hoover to leave a clear area. In the photo you will see that I left one fishplate in place on the adjacent rail, this was refusing to budge but won’t be a problem. You can also see the point motor bar and some dropper connections. A little bit more cleaning up of the ballast is still required in the right hand corner. My track is laid on cork and the ballast will lift quite cleanly from this, other surfaces may need a bit more cleaning up.

Step 7 – Put fishplates onto the adjoining rails at one end of the point only. It will usually be easiest to do this for the four rails at the diverging end but depending on your location you may need to do the other end. Use new fishplates of the same type as before, I had insulated fishplates on one track for my DCC block detection.

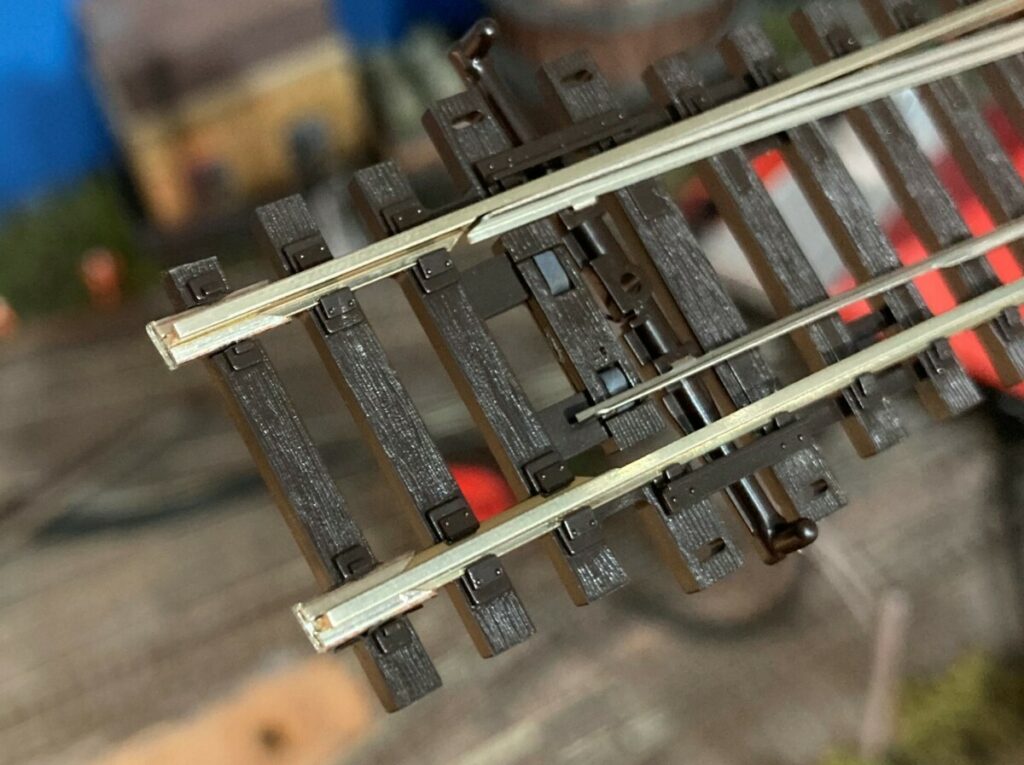

Step 8 – You can’t put fishplate on at both ends or it will be impossible to fit the new point back in to place (don’t be tempted to bend the point, this will cause permanent damage). To get around this I have developed a neat trick. Slide fishplates on to the other end of the new point pushing them in as far as they will go. Then use the cutting disk to cut off the half that sticks out, leaving a half length fishplate. In a following step you will slide this back on to the adjacent rail to join up the track.

Note: It’s important to cut the fishplates when attached to some rail. If you attempt to cut them when not attached they will close up making them useless. If you are nervous about cutting them on the end of the new point you could do it on a scrap length of rail and then transfer them.

Step 9 – Carefully fit the new point, joining it in to the new fishplates fitted in step 7. This is one of those tasks where an extra hand would be useful! Take your time to line things up and don’t force anything. If there are bits of ballast still in the way remove them, the baseboard under the point must be smooth. I had to trim the end of a sleeper back to get the point to fit into the junction. I was also lucky that I managed to get the point motor pin to go back in to the tie bar but you may need to remove the point motor and refit it afterwards.

Step 10 – With the new point laid in place, use angled pliers to gently move the half length fishplates (cut in stage 8) on to the adjacent rails. They don’t need to go on very far, just far enough to ensure the rails are correctly aligned. Use some track pins to hold the new point securely. Check that all the rail joints at each end are smooth then solder the joints and connect back any droper wires. Finally if you had to remove the point motor connect it back up.

Important: Test run some trains through the point at this stage and ensure the point motor works. Any issues with misalignment or bad electrical joints need to be fixed now.

Step 11 – Carefully sprinkle in some new ballast around the edges of the new point. Because of the cuts made in step 2 the area to be repaired should be minimal. Use a ballast that will match the surrounding area. Mist the area with water then fix the ballast with diluted PVA in the normal way. Allow the ballast to dry before proceeding.

Step 12 – Once the ballast is dry you can finish the area off. My track is sprayed with ‘sleeper grime’ colour so it is quite easy to blend the repair back in. Depending on the scenic finish around your track you may have some more scenic work to do in order to blend the repair back in. Clean paint and glue off the surfaces of the rail with a track rubber. Make sure that there isn’t any ballast in the gaps through the point ‘vees’ or between the check rails and avoid getting paint on the moving parts of the point.

Completed – Once everything has set you can re-attach any details that you had to remove, or any nearby details that were disturbed during the work. There is a very slight colour difference to the repaired area but this will even out over time.